- 1F, 2F, 3F, and 4F. Positions a fillet weld are welded in. Draw a welding symbol with a fillet weld on the other side, field weld symbol, and weld all-around symbol.

- One thing that is important to note about this type of weld is that you do it on the outside of the corner. The different weld types in a corner joint are as follows. 1- Fillet weld 2- Spot weld 3- Square-groove weld or butt weld 4- V-groove weld 5- Bevel-groove weld. 6- U-groove weld 7- J-groove weld 8- Flare-V-groove weld 9- Edge weld 10- Corner-flange weld.

- If you're welding overhead, for instance, you've got to move fast or the weld metal will end up on your face shield, rather than in the joint. After preparing a joint for welding, selecting the appropriate rod (if stick welding) and choosing the right machine settings, a welder must use a certain kind of hand stroke (and the right speed) to get.

- MIG welding was developed in the 1940's and 60 years later the general principle is still very much the same. MIG welding uses an arc of electricity to create a short circuit between a continuously fed anode (+ the wire-fed welding gun) and a cathode ( - the metal being welded).

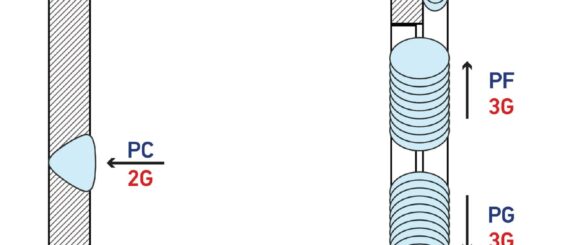

The way this system works is the position is first stated with a number, then right next to it the letter specifies the type of weld joint used. Here are some examples: 1F is a flat weld done using a fillet joint. 2F is a horizontal weld done using a fillet joint. 3F is a vertical weld done using a fillet joint.

Welder Certification simply means that the welder has demonstrated proficiency in the type of welding that will be performed at the job site using the procedures outlined. The weld must be witnessed by a WJMG Certified Welding Inspector (CWI), then the paper is sent to the employer or Project Manager.

Self employed welders hold their own certifications.

How Long is A Certification Valid?

Certification is valid for six (6) months, when the certification is used consistently and can be documented as such, it can remain valid during that time, even over years.

1f Welding Position

Can a Certification with One Company be Used at a Different Company?

Usually the new employer will require the welder to re-certify. The reasoning behind this is differences in their written procedures and liabilities. It is easy to be re-certified and generally the new employer will cover the costs.

What types of Welding Would Have to be Demonstrated?

Welding 1f 1g

It depends on the job, the Employer's procedures, etc.

- 1F, 1G - a flat position in a 1F (Fillet) or 1G (Groove)

- 2F, 2G - a horizontal position in a 2F (Fillet) or 2G (Groove)

- 3F, 3G - a vertical position in a 3F (Fillet) or 3G (Groove)

- 4F, 4G - an overhead position in a 4F (Fillet) or 4G (Groove)

- 5F, 5G - a pipeline weld where one or both ends are fixed, the weld direction changes and the positions maybe flat, vertical or overhead. 5F (Fillet) or 5G (Groove)

- 6G - a pipeline weld, the most generous of all certifications. The pipe will be unmoveable and the weld will need to be at a 45 degree angle. A 6G certification will certify the welder for all positions.

What Should the Welder Bring to the Test?

The welder must have a copy of the procedure that they will be certified on, the (PQR) and be dressed in PPE for welding. WJMG can provide the welding machines and coupons or the welder can bring their own.

The welder being tested must also bring the completed paperwork (you can download it here) and a copy of their driver's license or state ID.

Codes and Procedures:

The code and procedure will be determined by what type of job the welder is being certified for. There are structural welding tests, pipe welding tests, aerospace welding tests, food service welding tests and more.

- Structural welding, for architectural construction involves compliance to the American Welding Society (AWS) D1.1 structural welding code.

- Pipeline welding as in 'Alaska pipeline' usually involves the American Petroleum Institute (API) 1104 code book.

- Pressure vessels and boilers have their own welding code book too (ASME Section IX) and so does the Aerospace industry (AWS D17).

There are several dozen different welding codes for all types of welding projects. It is always best to become familiar with all codes relevant to the upcoming project. The Project Manager should have a copy of the code and the procedures that outline what type of certification is required.

How Much Does Welder Certification Cost?

Pricing varies depending on what types of tests and materials are involved and what paperwork is needed. The basic weld tests start at $150 each. Call Vicki at 303-451-6759 for more information and scheduling. Payment is required at the time of testing.

In Summary:

Welder Certification simply means that the welder has demonstrated proficiency in the type of welding that will be performed at the job site using the procedures outlined. The weld must be witnessed by a WJMG Certified Welding Inspector (CWI), then the paper is sent to the employer or Project Manager.

Self employed welders hold their own certifications.

How Long is A Certification Valid?

Certification is valid for six (6) months, when the certification is used consistently and can be documented as such, it can remain valid during that time, even over years.

1f Welding Position

Can a Certification with One Company be Used at a Different Company?

Usually the new employer will require the welder to re-certify. The reasoning behind this is differences in their written procedures and liabilities. It is easy to be re-certified and generally the new employer will cover the costs.

What types of Welding Would Have to be Demonstrated?

Welding 1f 1g

It depends on the job, the Employer's procedures, etc.

- 1F, 1G - a flat position in a 1F (Fillet) or 1G (Groove)

- 2F, 2G - a horizontal position in a 2F (Fillet) or 2G (Groove)

- 3F, 3G - a vertical position in a 3F (Fillet) or 3G (Groove)

- 4F, 4G - an overhead position in a 4F (Fillet) or 4G (Groove)

- 5F, 5G - a pipeline weld where one or both ends are fixed, the weld direction changes and the positions maybe flat, vertical or overhead. 5F (Fillet) or 5G (Groove)

- 6G - a pipeline weld, the most generous of all certifications. The pipe will be unmoveable and the weld will need to be at a 45 degree angle. A 6G certification will certify the welder for all positions.

What Should the Welder Bring to the Test?

The welder must have a copy of the procedure that they will be certified on, the (PQR) and be dressed in PPE for welding. WJMG can provide the welding machines and coupons or the welder can bring their own.

The welder being tested must also bring the completed paperwork (you can download it here) and a copy of their driver's license or state ID.

Codes and Procedures:

The code and procedure will be determined by what type of job the welder is being certified for. There are structural welding tests, pipe welding tests, aerospace welding tests, food service welding tests and more.

- Structural welding, for architectural construction involves compliance to the American Welding Society (AWS) D1.1 structural welding code.

- Pipeline welding as in 'Alaska pipeline' usually involves the American Petroleum Institute (API) 1104 code book.

- Pressure vessels and boilers have their own welding code book too (ASME Section IX) and so does the Aerospace industry (AWS D17).

There are several dozen different welding codes for all types of welding projects. It is always best to become familiar with all codes relevant to the upcoming project. The Project Manager should have a copy of the code and the procedures that outline what type of certification is required.

How Much Does Welder Certification Cost?

Pricing varies depending on what types of tests and materials are involved and what paperwork is needed. The basic weld tests start at $150 each. Call Vicki at 303-451-6759 for more information and scheduling. Payment is required at the time of testing.

In Summary:

- The welding procedure itself must first be qualified (or prequalified procedures can be purchased)

- Each welder must pass a certification test that resembles the tests used to qualify the procedure.

- Welders are only certified to weld within the limitations of the test they took to become a certified welder.

Disclaimer: welderportal.com is supported by its audience. When you purchase through links on our site, we may earn a small commission at no extra cost to you.

The welding position refers to the position of the welding operator towards the workpiece to be welded. Because of gravity, the welding position affects the flow of molten filler metal. It's important to understand the types of welding positions as different welding processes require to be performed at a certain position of the welder.

There are four main types of welding positions, which we will cover below.

Table of Contents

- 1 4 Basic Welding Positions

4 Basic Welding Positions

Flat Position (1G and 1F)

The easiest type to perform is the flat position, which is also sometimes called the downhand position. It involves welding on the top side of the joint. In this position, the molten metal is drawn downward into the joint. The result is a faster and easier weld.

In 1G and 1F, the number 1 refers to the flat position, while the letter G stands for a groove weld and letter F stands for a fillet weld.

Horizontal Position (2G and 2F)

This is an out of position welding position. It's a more difficult position compared to the flat position and it requires more skill from the welding operator to do them well.

2G is a groove weld position that involves placing the weld axis in a horizontal plane or approximately horizontal. As for the face of the weld, it should lie in an approximately vertical plane.

2F is a fillet weld position, in which the welding is done on the upper side of the surfaces that is approximately horizontal that lies against a surface that is approximately vertical. In this position, the torch is usually held at a 45-degree angle.

Vertical Position (3F and 3G)

In this position, both the plate and the weld lie vertically or almost vertically. The 3F and 3G refer to vertical fillet and vertical groove positions.

When welding vertically, the force of gravity pushes the molten metal downward and so it has the tendency to pile up. To counteract this, you can use either an upward or downhill vertical position.

To control this in the upward vertical position, point the flame upward, holding it at a 45-degree angle to the plate. This way, the welder will use the metal from the lower parts of the workpiece to weld against the force of gravity.

In the downhill position, the metal from the upper parts and the electric arc's kinetic force are used.

Overhead Position

In this position, welding is carried from the underside of the joint. It's the most complicated and difficult position to work in. The 4G and 4F positions stand for groove and fillet welds respectively.

1f Welding Test

In the overhead position, the metal deposited to the joint tends to sag on the plate, resulting in a bead with a higher crown. To prevent this, keep the molten puddle small. If the weld puddle becomes too large, remove the flame for a moment in order to allow the molten metal to cool.

1f Welding Positions

The positions flat, horizontal, vertical and overhead are the basic types of welding positions. However, they do not adequately describe pipe welding positions. Pipe welding can be done under many different requirements. These positions we'll cover in a separate article.